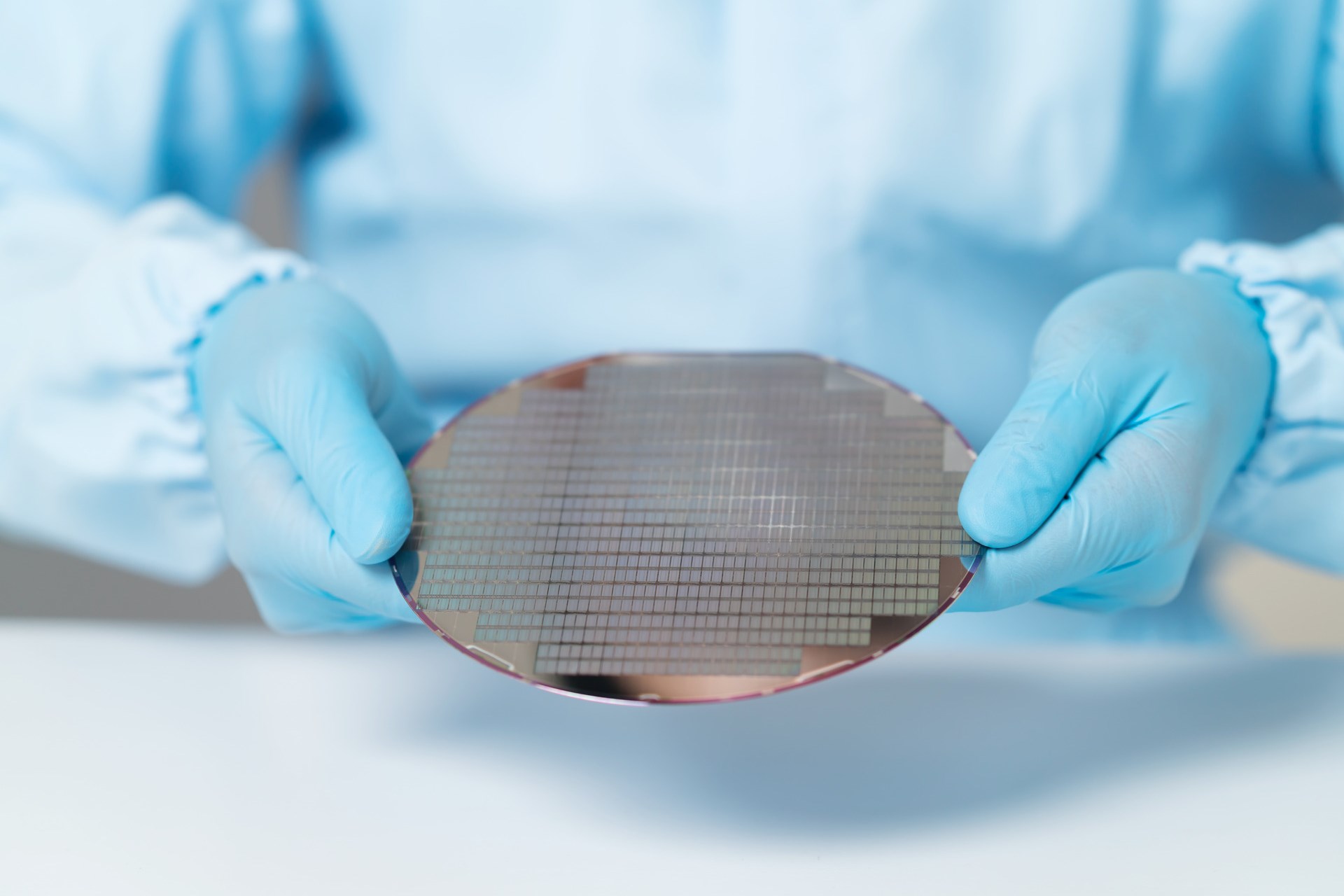

Ion exchange resins for the semiconductor and photovoltaic industry

Ultra-pure water (UPW) is indispensable for processing wafers or the complex, wet chemical procedural steps involved in photolithography in the production of micro- and nanoelectronics. Such processes are used to manufacture semiconductor components such as computer processors, memory chips, light-emitting diodes (LEDs), liquid crystal (LC) and LED displays, and photovoltaic modules. UPW is also used in microsystems technology for manufacturing and processing miniaturized mechanical components for micropumps, micromotors, and microvalves, for example. Ultra-pure water is an important prerequisite for preventing or removing deposits or impurities from delicate structures right down to the nanometer range that would otherwise result in production faults and indefensibly high reject rates. As electronics advances towards increasingly small dimensions, the quality requirements for UPW are becoming increasingly stringent.

Special ion exchange resins from the Lewatit® UltraPure (UP) series play a significant role in producing ultra-pure water reliably and efficiently. These include individual resins as well as working mixed beds and final polishers. They are all characterized by a particularly low release of organic matter and therefore contribute little to any increase in TOC concentration in the process sequence (low ΔTOC, total organic carbon). What is more, the discharge of metals and particles right down to the nanometer range is reduced to a minimum.

To produce UPW, fresh water or recycled process water is first demineralized. Then, it is taken through final polishing to reach the required extremely low levels of conductivity. After final polishing with special ion exchangers, the water obtained will be of the highest purity. If necessary, the particle content of the water is reduced further through a series of filtration steps.

In addition to the filtration steps, special ion exchangers enable the formation of particles due to resin erosion in the course of UPW production to be prevented from the outset. To that end, the aggressive hydrogen peroxide is removed from the water.

Our LewaPlus® design software can model various combinations of ion exchange resins and exchange stages on a made-to-measure basis and analyze their properties. This provides the user with maximum confidence that they will obtain the optimum treatment solution for the relevant feed water and the required process water quality for the given situation.

A special ion exchanger doped with palladium is suitable for eliminating the hydrogen peroxide that forms in photochemically induced radical processes during TOC removal in the process of UPW production due to UV irradiation of the water. Lewatit® K7333 is able to break down hydrogen peroxide catalytically, thus forming water and oxygen.

This can guard against erosion of the polymer structure in the ion exchanger for final polishing that is used in the last purification step. A possible source of tiny particles is thereby reliably eliminated.

In the production of UPW, the working mixed bed absorbs those ions that remain in the water following demineralization during pre-purification. In particular, these include complex anions with a relatively weak binding tendency such as silicate, borate, and hydrogen carbonate. Since these working mixed beds still absorb significant amounts of salts, regeneration of the resin components makes economic sense.

Final polishing is the last purification step for UPW that must meet the highest purity requirements as imposed for the production of highly integrated microprocessors, for example. Here, traces of ions in the ppb and even ppt ranges that the working mixed bed left in the ultra-pure water are removed in an ultra-pure final polishing mixed bed.

This is a reliable means of adhering to the specifications for electrical resistivity; residual content of metal ions, silicate, and borate in particular; and particle limits that are necessary for smooth, efficient production of high-quality semiconductor components.

In line with the variety of impurities that enter the water during the production process for semiconductor components or photovoltaic modules, waste water treatment is tailored for the impurities found in each application. Where etching processes are used, this involves treating the acidic waste water and removing fluoride in particular. Abrasives that contain copper are used in the chemical/mechanical polishing of wafers, with the result that copper that is hazardous for aquatic organisms also enters the waste water.

Waste water from photovoltaic cell production may contain environmentally harmful compounds of antimony, lead, cadmium, selenium, or tellurium, for example. Ion exchange using selective exchange resins is a proven and efficient method for even removing traces of impurities like these from the water reliably, thus preventing a risk to humans and the environment.